Farrat Elastomeric Bearings

Structural Bearing Design, Specification & Supply – Middle East

Unigroup provides engineering-led consultation, design support, and supply of Farrat elastomeric bearings for structural and civil engineering projects across the Middle East.

Working with Farrat, a global leader in movement control and vibration engineering, we deliver project-specific elastomeric bearing solutions that ensure long-term structural performance, durability, and compliance.

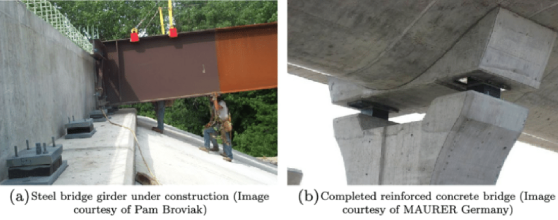

About Elastomeric Bearings

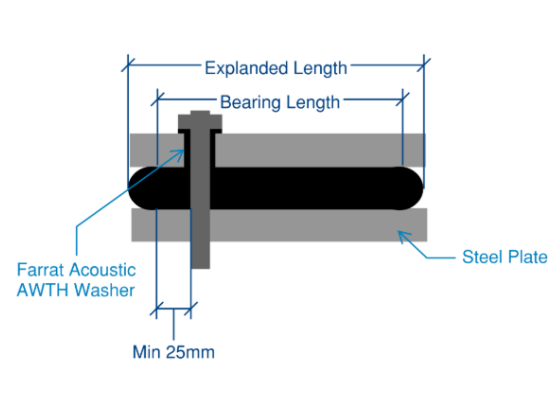

Elastomeric bearings are laminated structural bearings manufactured from elastomeric rubber layers sometimes reinforced with internal steel plates. They are designed to safely transfer loads while allowing controlled movement and rotation between structural elements.

Our Scope of Services

Design & Engineering Consultation

– Bearing type selection and sizing

– Load and movement calculations

– Compliance with AASHTO, BS, EN standards

Farrat Elastomeric Bearing Supply

– Custom-engineered bearings

– Technical datasheets and certifications

Regional Project Support across the Middle East

Typical Elastomeric Bearing Configurations

Laminated Elastomeric Bearing (Standard)

A multi-layer bearing consisting of alternating elastomer layers and internal steel laminates, bonded and vulcanized as a single unit.

Function:

- Transfers vertical loads safely

- Allows controlled horizontal movement

- Accommodates rotation at supports

Common Uses:

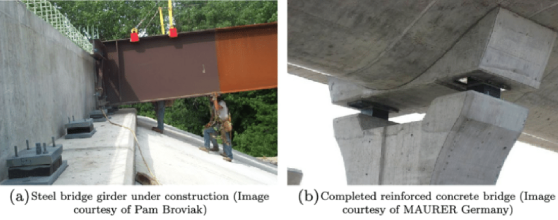

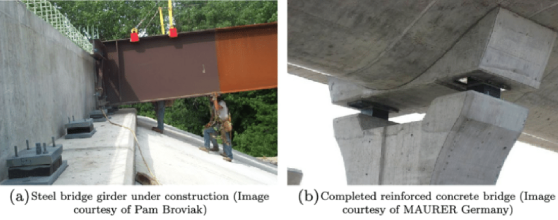

Bridges, podium slabs, transfer beams, industrial structures

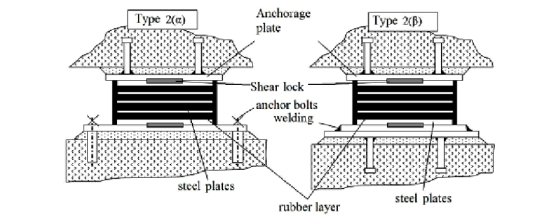

Reinforced / High-Load Elastomeric Bearings

Designed for higher vertical loads and reduced deformation, typically with increased laminate thickness or modified elastomer compounds.

Function:

- Eliminates the transmission of vibration through the building structures

- Supports heavy superstructures

- Controls shear strain

- Improves long-term creep resistance

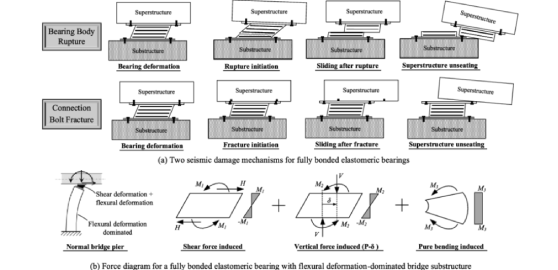

Seismic & Movement-Control Bearings

Specially engineered elastomeric bearings designed to perform under seismic, dynamic, or high-movement conditions.

Function:

- Dissipates energy

- Reduces force transfer to structure

- Protects columns, piers, and foundations

How Elastomeric Bearings Work (Simplified)

Elastomeric bearings work by:

- Compressing vertically under load

- Shearing horizontally to allow movement

- Rotating naturally without mechanical parts

This eliminates the need for sliding components, lubrication, or regular maintenance—making them ideal for long-life infrastructure projects.

Frequently Asked Questions (FAQ)

What is an elastomeric bearing used for?

lastomeric bearings are used to transfer loads, reduce vibration and noise while allowing movement and rotation between structural elements. They are most commonly installed between bridge decks and piers, columns and foundations, beams, podium slabs, or heavy industrial structures and foundations.

When should elastomeric bearings be specified?

They should be specified whenever a structure must accommodate:

- Thermal expansion and contraction

- Vibration isolation is required

- Differential settlement

- Rotational movement

- Seismic or dynamic effects

Early specification during the design stage significantly reduces long-term structural risk.

What materials are used in elastomeric bearings?

Most elastomeric bearings are manufactured from:

- Neoprene rubber or natural rubber

- Internal steel laminates for load control

The elastomer compound is selected based on environment, load, movement, and durability requirements.

Are elastomeric bearings maintenance-free?

Yes. Properly designed and installed elastomeric bearings are maintenance-free and have a long service life, often exceeding 50 years when correctly specified.

What standards govern elastomeric bearing design?

Elastomeric bearings are typically designed in accordance with:

- AASHTO

- BS / EN standards

- Project-specific authority requirements

Unigroup ensures full compliance during design review and supply.

How do I choose the correct elastomeric bearing?

Correct selection depends on:

- Vertical load

- Horizontal load

- Required movement

- Rotation capacity

- Environmental exposure

Unigroup provides engineering-led consultation to ensure the bearing is correctly sized and specified.

Can elastomeric bearings be used in seismic zones?

Yes. Elastomeric bearings can be engineered for seismic isolation and energy dissipation, significantly reducing forces transmitted to the structure.

Do you provide calculations and technical submittals?

Yes. For every project, we support with:

- Load and movement calculations

- Datasheets

- Technical submittals

- Installation guidelines

In collaboration with Farrat, all solutions are project specific.