ALUMINUM PANEL AND FACADE SOLUTIONS

CineSTEEL Quality

Specification

General Thickness :1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 5mm, 6mm etc

Product Features

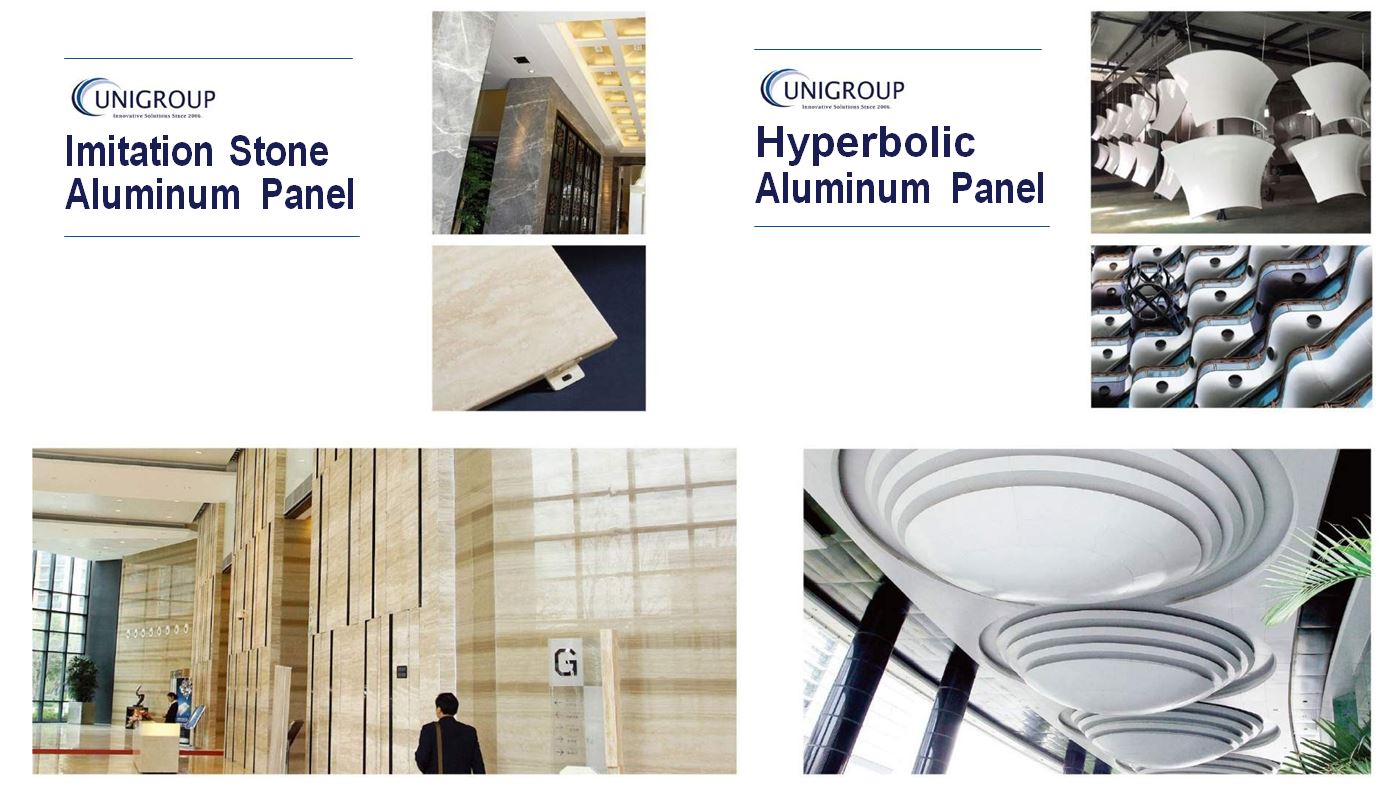

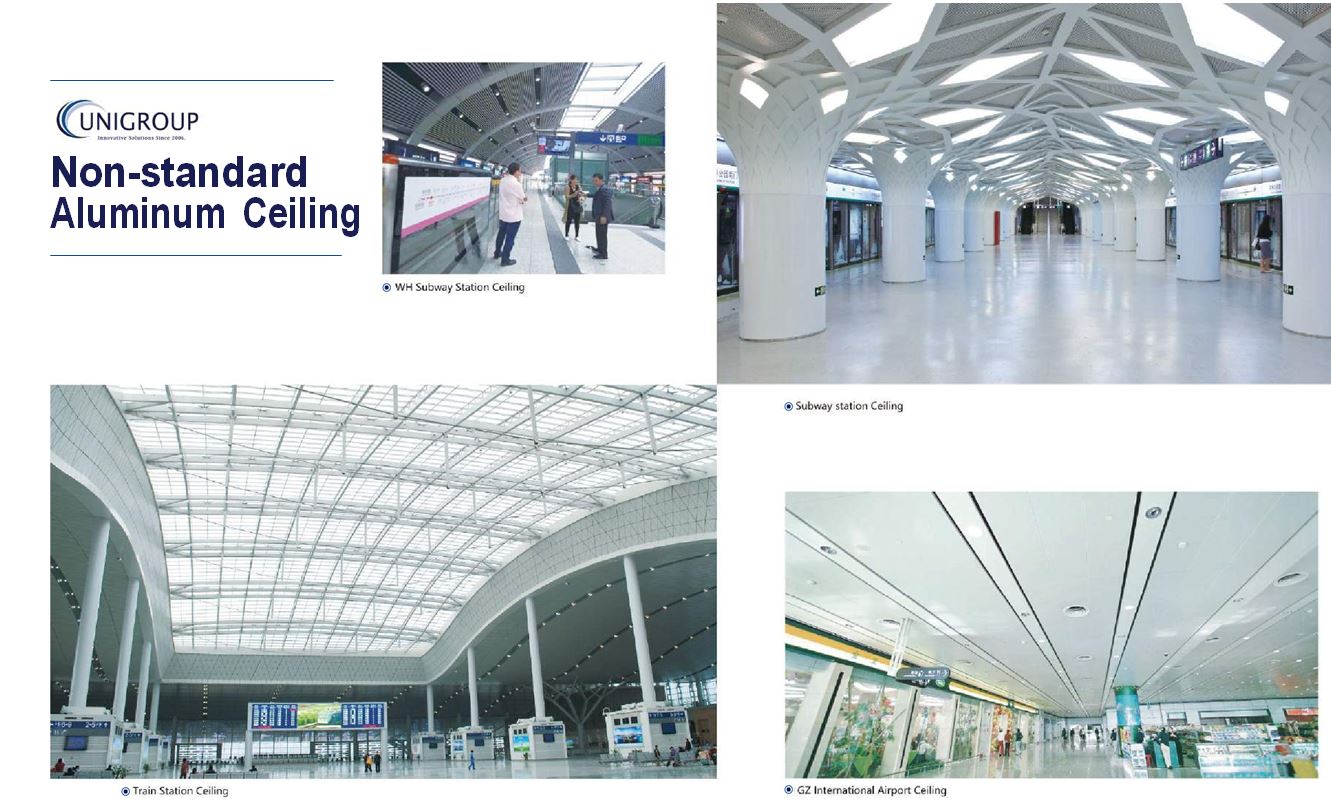

UNIGROUP brand aluminum panel is mainly used alloy 1xxx series, 3xxx series, 5xxx series as raw materials from global well-known suppliers. It is in light weight, good rigidity, and high strength; has good weathering resistance; easy to process and weld, can be processed complex shape such as flat surface, arc wall face, spherical surface, etc.. It has many colors to choose to make good embellishing effects. It has good stain resistance, it is easy to clean and maintain; easy to assemble and can be recycled, conducive to environmental protection.

Product Advantages

- Lightweight, good rigidity and strength;

- Non-flammable, excellent fire resistance;

- Excellent weatherability resistance, excellent ultraviolet ray resistance, superior resistance to acids and alkali, shelf life is 15 years without discoloration under normal outdoor environment;

- Good processing technique, plane, arc and round processing etc all are available;

- With complicated shape such as pagoda, difficult to get dirt, easy for maintenance and caring;

- Wide color selection, ultra good decoration effect;

- Easy to be recycled, with no pollution, good for earth saving

Specification

General Thickness :1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 5mm, 6mm etc

CineSTEEL Quality

Product Features

UNIGROUP brand aluminum honeycomb sandwich panels is the use of the current international advanced aviation technology combined with advanced automatic production equipment, making the aluminum and aluminum honeycomb core bonded to a high-tech environment-friendly decorative materials. We adopt continuous high-temperature compounding technology from German, use high-intensity heat plastic adhesion system, It comply with green product direction, with super weather ability fluorocarbon resin with colored pre-roll coating techniques. High strength, good rigidity, light weight, ultra-smooth, uniform color, sound and heat insulation, thermal insulation, moisture, fire, wind pressure, seismic, weather resistance, long life and easy installation, wide option for color and so on.Wha’s more, its’ cost performance is far beyond the traditional aluminum composite panel, which is truly “Green Environmental Protection energy conservation and really the first choice of material for modern decoration.

Specification

- 1)Top: aluminum spy sheet coated with fluro-carbon resin((pvdf) roasting painting

- 2)Core: aluminum honeycomb core, thickness of aluminum 0.4, 0.5 or according to customer’s requests

- 3)Botton: aluminum alloy sheet coated with polyester resin painting

- 4)Surface finish: treated with pvdf resin rolling roasting, surface coating thickness 30 m

- 5)Aluminum h3003 or according clients’request

- 6)Aluminum alloy sheet thickness: 0.5-1.2mm

- 7)Thickness: 6mm-30mm for decoration material

- 8)Size: width 1500mm<length<5800mm

Product Advantages

- 1. Light and straightness

- 2. Excellent rigidness

- 3. High intensity

- 4. Wind pressure resistance

- 5. Fireproof, sound and thermal insulation, shock absorption

- 6. Even coating and various colors

- 7. Easy to maintain and environmental protection